Differential Coating

Very high quality mirrors are required to make best use of the quality of x-ray radiation produced by the latest generation of synchrotrons. As the limits of conventional polishing technology are reached, it becomes necessary to consider other methods for improving the mirror slope error.

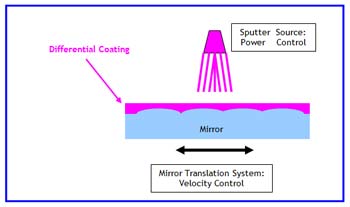

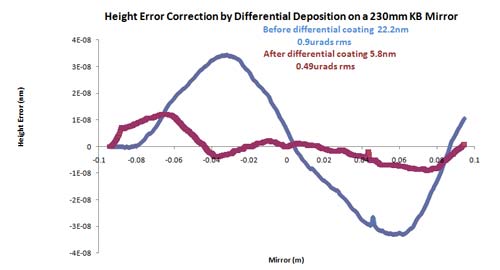

One approach is that of differential coating, in which the slope errors (deviations from the perfect shape) are corrected by selectively depositing material onto the mirror surface by using a magnetron sputtering technique – effectively "filling in" the low points on the surface.

Crystal Scientific have demonstrated this enhancement of mirror specifications by the process of differential coating. We have produced a number of plain mirrors, the largest being 1.2m in length, with slope errors of <0.7 microradian. Accurate and reliable measurement of these mirrors has been carried out with the help of the Diamond Light Source Metrology group and can now be done in house with our NOM system.

The development of this technique is discussed in the paper "A preferential coating technique for fabricating large, high quality optics" by S.G. Alcock and S. Cockerton. Click here to access the full paper.